Single Block Teak Wood Chopping Board – Rectangular Edge Grain Cutting Board

Price range: ₹999.00 through ₹4,499.00Premium Single Block PuliMutti -Tamarind Wood Chopping Board – P101

Price range: ₹999.00 through ₹1,499.00Thin Blank Teak Wood Vegetable Cutting Board

Price range: ₹1,499.00 through ₹4,999.00Premium Single Block Teak Wood Chopping Board Small

Original price was: ₹1,999.00.₹998.00Current price is: ₹998.00.Raised Teak Wood Chopping Board – Elevated Functional Design

Original price was: ₹1,999.00.₹1,798.10Current price is: ₹1,798.10.Solid Teak Wood Cutting & Carving Board with Juice Grooves

Original price was: ₹2,499.00.₹1,998.00Current price is: ₹1,998.00.Teak Single Block Medium Minimalist chopping boards

Original price was: ₹1,999.00.₹998.00Current price is: ₹998.00.Amra Farms Handmade Small Wooden Cutting Boards With Handle : Teak Wood Serving Board

Original price was: ₹1,999.00.₹1,998.00Current price is: ₹1,998.00.Amra Farms Tamarind Wood Butcher Block : Single Block Cutting Board

Price range: ₹799.00 through ₹1,499.00

Tamarind Wood Chopping Boards are becoming more and more popular in India and is making a big come back. There are a lot of wood available in India to make chopping boards from. Mango wood is widely available. India is the second largest producer of bamboo, so there are options to choose from bamboo chopping boards too. Teak is now affordable. Acacia is a great option too. But then why do people in southern India choose tamarind wood for cutting boards? This article explores some of the facts, trends and statistics on tamarind wood chopping boards, its market and uses worldwide.

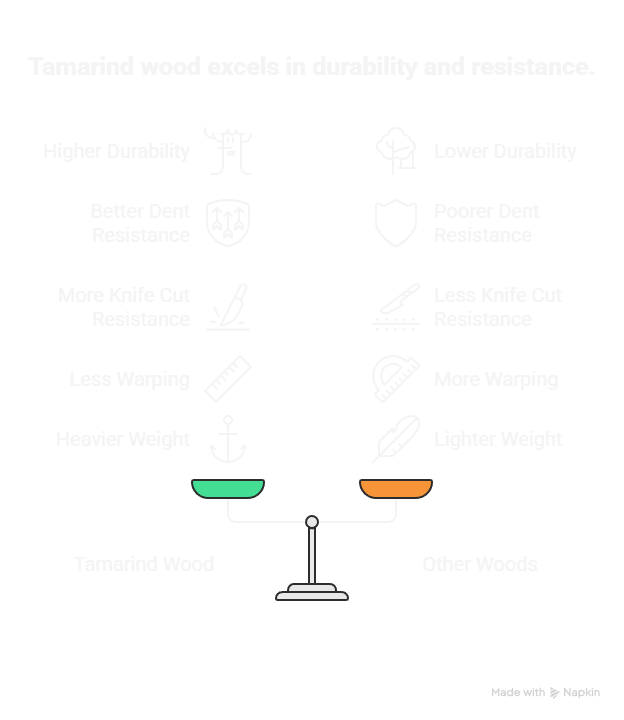

Durability and strength of tamarind wood is excellent

Yes. Tamarind wood is more durable than teak in most cases. The fibers are dense and the Janka hardness rating is 3650 lbf. It’s one of the highest for kitchen wooden cutting boards. They are 31% harder than mango wood making it more durable for chopping boards than the most widely used wood in India. An average tamarind wood chopping board lasts anywhere between 10 and 15 years with proper care. While this number may seem superfluous, it’s actually true. Some south Indian homes have tamarind wood chopping boards for more than a decade. And to even increase the life of the board, the end grain construction of tamarind wood chopping boards lasts 30% longer.

Tamarind wood is known to resist dents 40% better than acacia wood chopping boards. When it comes to knife cuts, tamarind wood can withstand up to 1000 knife cuts before any visible wear. This is due to the high wood density of approximately 0.85 g/cm³ providing natural durability. In comparison to bamboo, tamarind wood warps 50% less than bamboo boards and is 20% heavier than teak wood boards of the same dimension. Being a heavy duty board, tamarind boards can support up to 30 KG of weight without bending.

what makes tamarind ( Tamarindus indica ) special?

| Property | How it helps when you cut meat & vegetables |

|---|---|

| Medium‑hard Janka rating (~1 300 N) | Hard enough to resist deep gouges, yet soft enough to be gentle on knife edges. This balance keeps knives sharp longer – a big advantage in busy Indian kitchens where knives are used constantly. |

| Closed‑grain, low porosity | The dense grain does not absorb juices, blood, or oil easily. Moisture stays on the surface, so the board dries quickly and does not become a breeding ground for bacteria. |

| Natural antimicrobial compounds | Tamarind wood contains tannins and phenolic acids that inhibit bacterial growth. Traditional Indian cooks have long trusted this “self‑cleaning” quality for handling raw meat and fish. |

| High natural oil content | The wood’s own oils give it a smooth finish without the need for heavy external oiling. When the board is lightly oiled with food‑grade mineral oil, the finish becomes even more water‑repellent. |

| Resistance to warping & cracking | The wood tolerates the high humidity and temperature swings common in many Indian homes (e.g., hot kitchens, monsoon moisture). A tamarind board stays flat for years, preventing uneven cuts. |

| Light‑to‑medium weight | Easier to lift, clean, and store than very heavy hardwoods like teak, yet sturdy enough to stay in place while chopping. |

| Abundant & inexpensive locally | Tamarind trees grow widely across the sub‑continent; the wood is therefore cheap and readily available, making it a practical household item. |

| Non‑toxic, food‑safe finish | When finished with a simple food‑grade mineral oil or a natural beeswax blend, the board contains no synthetic chemicals, formaldehyde, or BPA – a concern for many Indian families. |

Cultural & Practical Reasons Behind Its Popularity

| Reason | Explanation |

|---|---|

| Traditional knowledge | Rural and urban Indian households have used tamarind wood for centuries. The practice is passed down through generations, reinforcing trust in the material. |

| Versatility for mixed cuisines | Indian cooking frequently moves from raw meat (e.g., kebabs, curries) to delicate vegetables (e.g., stir‑fried bhindi, salads). A board that handles both without transferring flavors or odors is essential. Tamarind wood’s low absorbency meets this need. |

| Ease of maintenance | A quick wipe with a damp cloth, occasional oiling, and the board is ready for the next round of chopping. In many Indian kitchens, a dishwasher is not common, so a board that can be hand‑washed and dries quickly is valued. |

| Aesthetic appeal | The warm amber‑brown colour of tamarind wood matches the typical Indian kitchen décor (teak, mango wood, etc.) and looks good when used as a serving platter for fruit or cheese. |

| Economic factor | Because tamarind wood is locally sourced, it costs far less than imported hardwoods (e.g., maple, walnut). For large families that need multiple boards (one for meat, one for veg, one for bread), the lower price is decisive. |

| Environmental friendliness | Tamarind trees are fast‑growing and often harvested from pruned or fallen branches, making the wood a relatively sustainable choice compared with slow‑growing exotic species. |

How Tamarind Wood Performs Compared with Other Common Indian Boards

| Material | Hardness | Porosity | Antimicrobial | Maintenance | Typical Use in India |

|---|---|---|---|---|---|

| Tamarind wood | Medium (Janka ~1 300 N) | Low | Moderate‑high (tannins) | Oil 1–2 × / month, hand‑wash | Everyday meat & veg |

| Mango wood | Softer (Janka ~1 000 N) | Higher (more open grain) | Low | Needs more frequent oiling | Traditional veg boards |

| Bamboo (solid) | Harder (Janka ~2 000 N) | Moderate (if not laminated) | Low‑moderate | Oil or wax, avoid soaking | Budget boards, occasional use |

| HDPE plastic | Soft (non‑hardness rating) | Non‑porous | None (but easy to sanitize) | Dishwasher, replace when scarred | Raw meat, poultry (color‑coded) |

| Rubber (silicone‑rubber) | Soft‑medium | Non‑porous | Often contains antimicrobial additives | Dishwasher‑safe | Professional kitchens, heavy chopping |

Food safety and hygiene of tamarind wood chopping boards

Tamarind wood is naturally antibacterial and known to kill most of the bacteria exposed to its surface. Research indicates 99.5% of all bacteria are killed within 24 hours on tamarind wood. By oiling the board regularly you further improve the board’s antibacterial features by 50% than dry tamarind wood. Being less porous than wood like oak, the liquid absorption of tamarind wood is less by 35% in comparison. With reduced moisture absorption, the wood ensures that they are not just antibacterial but also anti-fungal and mold resistant. Since they dry faster (by 15%) compared to beech wood boards, there is lesser risk of mold and fungus. Did you know that 65% of chefs trust a tamarind wooden board for its antibacterial features and use it to cut raw meat?

Though tamarind wood chopping boards are antibacterial, they do require care and maintenance. Deep cuts harbour 30% more bacteria in the wood if they are not maintained. Clean the board with lemon juice and salt or baking soda scrub to reduce bacterial growth. Boards cleaned with lemon have 25% fewer bacteria than those cleaned with soap only. The tannins in tamarind wood inhibit fungal growth and this also improves the life of the board. 39% of tamarind chopping board owners do not oil their board and this results in cracks and warps. Maintaining your wooden chopping board is key for food safety and lifespan of the board. The design of the board too plays a major role in contamination spread. Boards with juice grooves are known to have 18% lesser contamination spread compared to flat ones!

Shop Tamarind Wood Chopping Boards

Amra Farms Tamarind Wood Butcher Block : Single Block Cutting Board

Price range: ₹799.00 through ₹1,499.00Premium Single Block PuliMutti -Tamarind Wood Chopping Board – P101

Price range: ₹999.00 through ₹1,499.00Tamarind Wood Extra Large Single Block Chopping Board

Original price was: ₹5,939.01.₹5,344.11Current price is: ₹5,344.11.

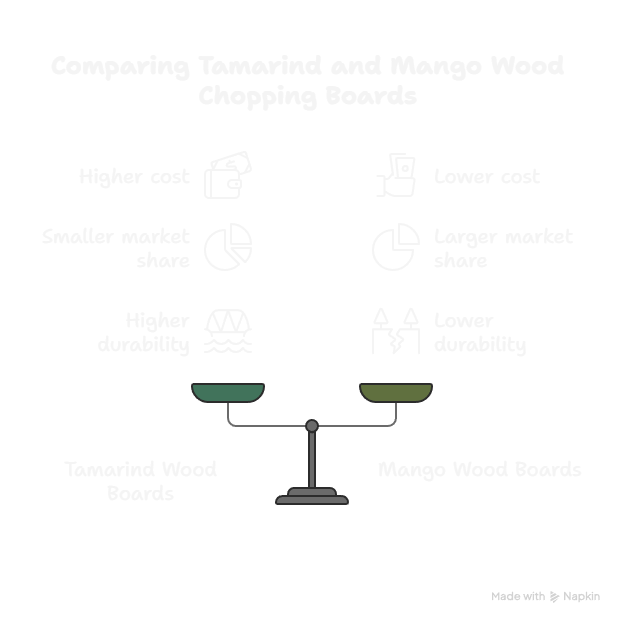

Tamarind wood market and usage

Tamarind wood is mostly used in the Asian subcontinent and accounts for 9% of the premium chopping board market. 40% of thelocal wooden chopping board sales come from tamarind wood, mostly from southeast Asia and India. While the export demand for tamarind chopping boards has increased globally by 20% since 2020, they are far behind other wooden boards and bamboo boards in the competition. 60% of all tamarind wood boards sold globally are handcrafted. Tamarind wood is hard to work with as they are more dense. This makes tamarind wood chopping boards more expensive. Tamarind boards are 25% more expensive than mango wood chopping boards while they are still cheaper than teak and walnut. Online sales of tamarind wood chopping boards have increased by 35% since 2023 even with the higher costs and competition from mango wood. 80% of all tamarind wood chopping boards sold are of end grain variant. This contributes to mostly butcher boards which are sold as single block, live edge cutting boards for cutting meat. End grain variants are rare due to lack of awareness and the high price of construction compared to mango wood. Tamarind wood boards are chosen for their durability by 70% of the buyers. While very common in India and Asian countries, tamarind wood is marketed as a luxury kitchenware in Europe and North America and charged at a premium price.

Sustainability and environmental impact of tamarind wood chopping boards

Tamarind trees are fully sustainable and grown in abundance in southern part of Kerala, specifically Tamil Nadu, Andhra, Karnataka and Kerala. Tamarind boards are made from by-product wood in most cases, reducing the waste by 50%. Each tamarind board saves 1.5 kg – 3 kg of wood waste from being discarded or burned. Tamarind wood is harvested from trees that are old, mature and often crossed the age of 70 or 80 years. These trees are weak and often cut down to reduce accidents. The tamarind boards have a 30% lower carbon footprint compared to plastic boards and 90% of the tamarind boards are non-toxic and come with a food safe finish. These boards are fully recycled at the end of their lifecycle. Tamarind trees are planted to reduce soil erosion in tropical regions and require minimal care. They are tough trees which can survive long drought. Tamarind boards use 20% less energy in production compared to bamboo boards and 80% of tamarind wood board makers use a solar powered kiln for drying. Overall, the entire process is eco-friendly and sustainable.

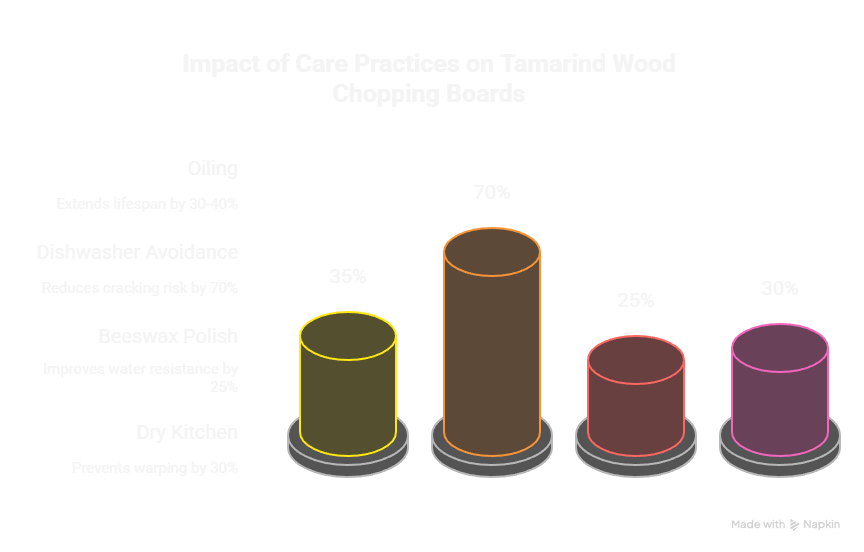

Maintenance and care of tamarind wood chopping boards

Oiling your tamarind wood chopping boards extends the lifespan by 30-40%. We recommend mineral oil or fractionated coconut to maintain your board’s colour by 3 times. Do not use olive oil and cooking oil that tend to go rancid. Handwashing the board is key to maintaining your wooden chopping boards. 70% increase in risk of cracking is due to dishwashers. Your tamarind wood chopping boards will have to be sanded every 2-3 years to maintain its smooth surface. Applying beeswax polish improves your board’s water resistance by 25% and improves the life of the board too. When drying the board, keep them upright to dry them twice as fast. Humidity plays a major role in your board’s lifespan. A dry kitchen prevents warping by 30% compared to a humid area. Ensure your kitchen is well ventilated. Tamarind wooden chopping boards retain their shape even after 5000 cleaning cycles. Small cracks are easily repaired 90% of the time and you do not have to discard your board. Ensure that you take care of the board immediately when you see cracks in them.

Design and feature preference in tamarind wood chopping boards

Tamarind boards come in 20+ unique patterns. From distinct unique natural grain patterns and spalting, tamarind wood is amazingly beautiful with the right wood. No two tamarind boards are identical due to their natural variations. Double sided tamarind wood chopping boards extend the usability by 35% while also adding to the functionality by using one side for meat and the other for vegetable. Custom engraving requests in Tamarind boards orders are up to 20% and these are usually as gifts for housewarming or other occasions. Juice grooves in tamarind boards are 40% more popular in boards than flat designs and a handle groove reduces accidents by 15%.

The best part about tamarind wood chopping boards are that it can be as thin as 1.5 cm without losing strength. Large tamarind boards can measure up to 60 cm in length for heavy duty use. Boards with rubber stoppers lips or feet tend to reduce slip by 50% and a rounded edge adds for better grip and aesthetics.

Chefs Preference and popularity

Chefs are experts when it comes to kitchenware. Professional chefs have gone through a stream of products in their lifetime from small utensils to extremely large complex cookware. The chopping board is not new to any chef and most of them have gone through all types of chopping boards from complex designs to minimalist wooden boards. But among all the chefs who have tried the tamarind wood chopping board 75% of professional chefs rate tamarind boards as highly durable. 50% home cooks choose tamarind boards for chopping vegetables and it is 25% more popular than plastic boards in Indian household. A blind test shows that the feel of a tamarind board is more preferred than bamboo by 80% and more than 40% of pastry chefs love the tamarind board for kneading dough. The heavy duty board stays in place and does not slip or slide easily. More than 70% of the people cite the boards visual appeal as a purchase reason. Though the tamarind wood chopping boards have lesser dominant grains they have the spalting which gives it a unique look. Many Michelin star kitchens use a tamarind board for presentation platters. For professional chefs, 9/10 times they found the tamarind wood chopping boards as knife friendly. They are a popular rustic kitchen theme choice worldwide.

Knife and cutting performance of Tamarind wood chopping boards

Tamarind boards are gentle on knives and reduce dulling by 20% when compared to plastic boards. The hardness of the board prevents deep cuts while maintaining the smooth surface 2 times longer. Serrated knives cause 40% lesser damage on tamarind boards when compared to bamboo boards and tamarind wood is 30% less abrasive than glass or ceramic boards. The board is known to be self healing. The knife damage can further be reduced on an end grain chopping board by 50%. The use of heavy cleavers is safe without splitting the wood. The wood is dense and can be used for meat as a butcher board. The even surface can be maintained even after years of heavy chopping.

Cultural and traditional relevance of Tamarind wood chopping boards

Tamarind boards have been the primary material for chopping boards in an Indian household for centuries. They are predominant in the south Indian kitchen. The Ayurveda indicates tamarind to have purifying properties. Used traditionally for pickling vegetables and is symbolic in Heritage cooking practices. Known as imli, Puli or huli in parts of India, they are known to be once used as temple kitchen tools. Boards are often paired with stone grinders in traditional kitchen.

Tamarind wood is light in colour with spalting creating a unique pattern in some wood. The wood is dense and often weigh 4-5 KG for a large sized board. They are known to retain 20% more natural oils than tamarind wood and have excellent shock resistance reducing breakage risk and making it one of the best material for butcher blocks, specially cutting meat which have heavy bones. They are more termite resistant and pest resistant.

Shop Spalted Tamarind Wood Chopping Boards

Wild, Durable, Versatile, Tamarind wood cutting board with bold patterns