Your cart is currently empty!

Why are some chopping boards more expensive than others

When purchasing a wooden cutting board most of us wonder why it’s so expensive. At the end of the day it’s just a piece of wood. For a woodworker it may take a day to complete the job but it’s a lot more than that for some cutting boards than others. While most cutting boards are standard design with a rectangular shape, there are others which are more than a block of wood. It’s more of an art form than a cutting board. For instance, would you believe that a cutting board sold for $3250? That’s approximately 2,60,000 Rs. And that board was just 4 x 12 inches. Yes, that’s true. The cutting board by Wharton Esherick sold for a whopping 2.6 Lakh rupees. Why so expensive? Let me explain.

Understanding the wood

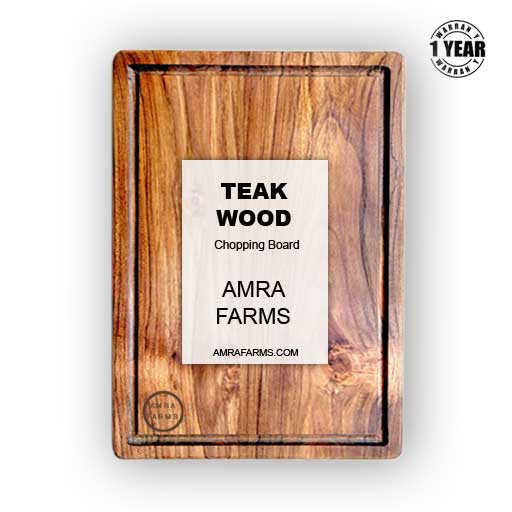

Shop Teak Wood Chopping Boards

Teak Wood Butcher Board (15 x 12 x 1 inch)

₹4,999.00Teak wood Meat Chopping Board (15 x 12 x 1 inch)

Original price was: ₹2,499.00.₹1,299.00Current price is: ₹1,299.00.Teak wood Steak Cutting & Serving Board (15 x 12 x 1 inch)

Original price was: ₹4,999.00.₹4,099.00Current price is: ₹4,099.00.Elegant Teak Wood Cheese Board (18 x 13 x .75 inch)

Original price was: ₹2,999.00.₹1,999.00Current price is: ₹1,999.00.

Woodworkers are experts in crafting objects from wood. But they vary widely in terms of understanding wood. While some woodworkers understand the craft, not all of them understand wood. The type of wood they work with, the grains, the patterns and a deep understanding of the fibres make great woodworking possible. Crafting a piece of chopping board, exposing the exotic wood grains prominently even with the natural wood imperfections is not craft. It’s art. There is a significant difference between both. Anyone can learn a craft. But it takes time and persistence to master art.

A great woodworker, an artist in his craft will understand the unique wood grains, wood colour variations, grain directions in wood apart from the type of wood. They are experts in cut styles and understand how the grains are exposed with plain sawn, rift sawn, quarter sawn and live sawn wood cuts. They know how to display wood board with knots to create a character out of the board.

The difference between a board that you purchase off the shelf vs a board created by an artist differs not just in price, but the understanding of the wood in depth by the craftsman. This understanding assures that the craftsman takes a great amount of time crafting the wood to express the beauty of the wood as much as ensuring the durability and functionality of the object.

The art behind the craft

A chopping board that is rectangular with a juice groove and a handle is what woodworkers call functional. They could be end grain or edge grain. It does not matter. At the end of the day it’s just a plain piece of wood designed to meet a requirement. The purpose is met. You need a chopping board to cut vegetables, bread and meat and you have it. But when it involves art, it’s different. There is a vision behind what is produced. An imagination is put to life with these boards. With end grain chopping boards the designs are usually checkered boards but they have evolved lately. From 3D designs to very unique patterns, end grain boards are priced upon the complexity of the design itself. For edge grain boards, the shapes of the board determine the price. The more imaginative, yet functional boards are the ones which are priced more. Remember, no matter what shapes or designs the boards are, they have to align with the features of the wood’s grains, finish and wood grain orientation.

Custom Design

Standard designs are common. When a product is unique they demand attention. A new product which is of an entirely new design, which is different from the standard ones usually attracts more people towards it. Rectangle and round boards are common now. Live edge boards are unique. Each of the boards is different, ensuring you have a unique piece in your collection. No one will have the same design, same wood patterns and construction. Custom designed boards, that are made to order or designs which are unique are difficult to find too. Unlike those that are bulk manufactured, custom design boards with your name and logo usually take dedication and time.

Some homeowners love to have their family name engraved in their board or they would like to gift a board with custom engraving for their friends and family. Others, like collectors want a unique piece that will align with their home and kitchen design. These boards are custom created, the wood chosen to match your design. The designs are unique and you can be assured that there will be no other board similar to the one you have in every way.

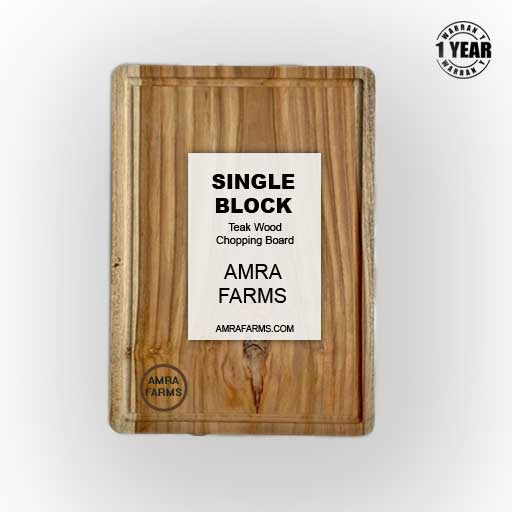

Single Block Vs Joins

Single Block Chopping Boards

Premium Single Block Teak Wood Chopping Board

Price range: ₹1,499.00 through ₹2,999.00Premium Tamarind Wood Chopping Board – Single Block

Original price was: ₹3,499.00.₹1,999.00Current price is: ₹1,999.00.Single Block Natural Wooden Chopping & Serving Board (25 x 15 x 1 inch)

Original price was: ₹999.00.₹749.00Current price is: ₹749.00.XL Single-Block Wooden Cutting Board ( 45 x 30 x 2 cm )

Original price was: ₹1,899.00.₹949.00Current price is: ₹949.00.

One of the other factors that makes a chopping board expensive is the construction of the board itself. Single block wooden cutting boards are much more expensive than cutting boards that are joined. While the work involved in creating a single block cutting board is much lesser, the price of the wood itself is much higher per square inch of the board. A wooden board which is 8 inch wide is nominally priced but a wooden board at 12 inch width will cost more per inch than the smaller counterpart.

Single wood boards, as the name suggests are constructed from a single piece of wood. Most of the wooden board has to be the heartwood (up to 90%). This requires the original plank to be at least the width of the board itself. The length is immaterial. The wider the plank, the older the tree. This ensures that the wood is denser, durable and aged. A single block wooden chopping board often comes from trees that are more than 30, or even 50 years old, some older than 70. Unlike a joined construction which can be made from wood which are just 10 or 15 years old and joined together, single block boards come from really old, aged trees. The older the tree, the more expensive it gets.

The price is not for the age itself, but for the features it comes with. With older trees, the boards are denser, have richer grains, the heartwood is stronger and the beauty of the board itself is often enhanced with different fibre types due to the compression of the wood and different weathering it goes through.

Durability and Thickness

Wooden boards that are less than an inch thick are usually cheaper than boards which are more than an inch thick. A wooden chopping board can be anywhere between half an inch to 3 inches. Thicker boards are often more uncomfortable to move, and lack mobility but they are more expensive due to its durability and the material required. More thickness means more wood, which means more expense for material.

The wood’s durability depends a lot on the thickness of the wood. Wood like mango requires at least 1 inch thickness to ensure they do not bend, warp or crack. Teak on the other hand can be up to 2 centimetres, just short of an inch for good durability and a longer life. A teak wood single block 1.5 inch thick chopping board will come with a guarantee of 10 or even 20 years. The life decreases by half the moment you bring the thickness of the boards to less than an inch. The same applies to most wood.

Handcrafted Finish

Mass produced boards are much cheaper. This is common with the standard boards which are rectangle or round. These are boards which come in a standard size and available in plenty. These boards are not crafted with imagination or creativity. Most of these boards are not cared for during construction. The manufacturers are not craftsmen but a production unit. They churn out cutting boards in bulk, without considering the material, the grains in the wood or the quality of the wood. The result is often a simple board with whatever material is available, often a disrespect to the beauty and value of the wood.

Handcrafted boards are different. The artisans take time to construct these boards, considering the grains, the fibre orientation, the thickness consideration and focusing on putting the natural beauty of the wood to the front. Handcrafted boards, some may seem imperfect but they are always unique and perfect in its own way.

So next time you come across a board which is expensive, don’t wonder why it is so pricey. Apart from some brand names who want to cash in on their brand name and have a heavy price tag, most other boards are priced based on these above factors. If you do find a board which is exorbitantly priced and not sure why, take a good look at the board, the construction, the wood type and material apart from the construction.

Categories

Products

Recent Posts

- Salmonella on Your Cutting Board? What Science Says About Plastic and Wooden Chopping Boards

- MasterChef Pankaj Bhadouria inspired chopping boards in Teak

- Ranveer Brar Inspired Chopping Board in Teak

- Teak Wood Guide: Benefits, Types, and Uses of the World’s Most Durable Hardwood

- Teak Wood Vs Acacia Wood Chopping Boards: Which is the Best Wood for Your Kitchen?